Coastal Development and Shrinking Marine Habitat – a Problem for All

Nearly 60% of the human population lives along coastlines. As more people migrate to coastal urban centers, increasing coastal development and urbanization is inevitable. At the same time, climate change risks like flooding and stronger storms are already creating immense challenges.

Pressures from water and land are squeezing our coasts; they come with serious implications not only for marine infrastructures and industries but also for the people and the coastal organisms that live there—the long-term effects of losing critical coastal systems will ripple out globally.

Structures like seawalls, breakwaters, and offshore wind turbine bases are often built to blunt the effects of rising seas and a changing climate, yet their manufacture and construction contribute to our carbon crisis.

Emissions in Concrete Manufacturing

Concrete accounts for 8% of global carbon dioxide emissions, and is used in 70% of marine infrastructures. The production process of concrete, made largely with cement, produces a significant carbon footprint in 2 main ways:

- The use of fossil fuels to kiln-fire limestone into quicklime.

- The large quantities of carbon dioxide released during calcination (the chemical transition of limestone to quicklime; CaCO3 → CaO).

Between 50-60% of the CO2 produced is during calcination. The remaining carbon dioxide emissions are a result of the fossil fuels used to power this conversion process. According to the Portland Cement Association, for every 10 kg (22 lbs) of Portland Cement produced in the U.S., 9 kg (20 lbs) of CO2 are emitted.

Emissions Post Deployment: Losing Carbon Sinks

Concrete’s carbon footprint continues to grow after production. Concrete not only displaces natural habitats, but also impairs the ability of marine life to regrow at the installation site. Why is this relevant to carbon emissions?

The oceans are a massive carbon sink (i.e. systems that store more CO2 than they release). When most people think of carbon sinks, they think of ecosystems like the Amazon or Boreal forests, famously dubbed the “lungs of the earth”. Our oceans, however, also function as one of the world’s most important carbon sequestration sites, removing approximately 30% of current anthropogenic CO2 emissions.

One way in which the ocean stores carbon dioxide is through a process called carbonation. Carbonation (also called mineralization) happens when CO2 combines with calcium—converting carbon dioxide into calcium carbonate (CaCO₃): the same material as limestone, chalk, and oyster shells. When many sedentary species of marine life grow, they assimilate carbon dioxide and calcium into their skeletons. Species like oysters, corals, tube worms, coralline algae, and barnacles have vast potential to store the greenhouse gas in their shells. When coastal ecosystems are disrupted with concrete infrastructure, these marine creatures lose their habitats and no longer capture carbon to the same degree.

10% of the sea is coastal, and 90% of marine species live in coastal waters. Losing these ecosystems and their productivity will not only impact marine food webs by reducing breeding habitat, feeding grounds, and growing spaces for our most iconic and productive marine ecosystems (sea grass, mangroves, coral reefs, oyster reefs), but will also impact the services we humans receive from ecosystems, like reduction of wave energy, food, and climate regulation.

Lowering Concrete’s Emissions

One way to reduce embodied CO2 is to use less carbon-intensive cement. Byproducts of other industries can step in, replacing Portland cement with fly ash or slag cement, which contains granulated blast furnace slag (GGBS). When slag cement replaces 50% of the Portland cement in a mix, there is a 45% reduction in greenhouse gas emissions per cubic yard of concrete. For example, a Canadian startup, CarbonCure, have developed an innovative method of producing concrete that traps carbon dioxide emissions and binds it within the concrete forever, while at the same time reducing the amount of cement used to make concrete. Nanotek on the other hand, developed revolutionary technology in sustainable cement production. They transform Portland cement into Nano cement. The technology gives the opportunity to reduce CO2, NOX, and SO2 emissions by 2-3 times per ton of cement and have production cost savings of over 30%. Their Nanotechnology results in high-performance cement and concrete, that are more sustainable, and do not call for heavy reconstruction of cement facilities.

Another way to reduce CO2 emissions is by incorporating unique additives into concrete mixes, such as ECOncrete’s admixture, which is composed of 92% recycled materials that would otherwise end up in landfills. When incorporated at 10% of the cementitious materials in a mix, and used in combination with 60% slag cement or fly ash, ECOncrete’s admix can reduce the carbon footprint of marine infrastructure by up to 70%.

ECOncrete addresses a global need: lowering the footprint of one of the hardest materials to decarbonize, concrete. Within the marine construction industry, the need to reduce concrete infrastructure’s environmental footprint is acute.

ECOncrete’s Eco-Engineered Technology

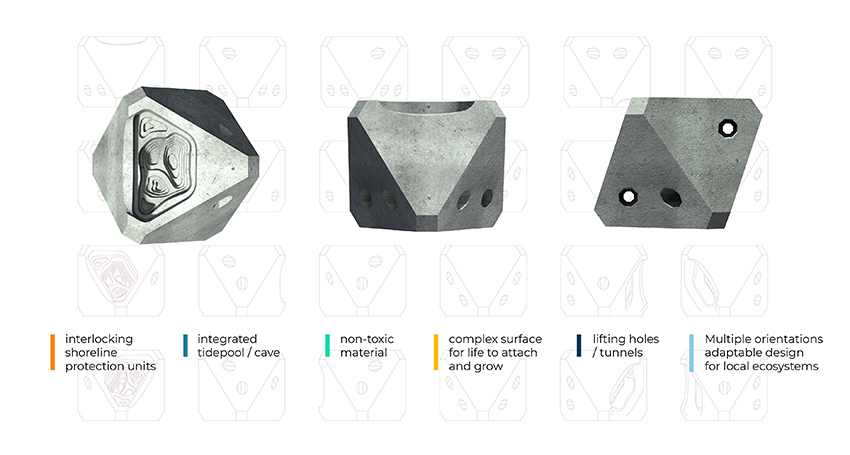

Traditional concrete marine infrastructures have three design failures that lead to a low diversity of marine life, and poor biological productivity. When changes are made to three features, biodiverse marine life can thrive on concrete, and infrastructure can actively store carbon dioxide.

- Chemical composition – Traditional concrete is known to be toxic to many marine organisms, mainly due to its surface chemistry. When free-floating marine larvae (the juvenile states of some sedentary organisms like tubeworms) attempt to settle on concrete, inhospitable surface chemistry discourages them. Instead, invasive species can more easily colonize and tilt the balance towards an unhealthy ecosystem.

- Surface texture – Traditional marine infrastructures have flat-plane, homogeneous surfaces. Ocean currents sweep past these flat, dense planes. This is because, unlike rough natural marine surfaces, smooth concrete doesn’t provide the micro-turbulences larvae need to be slowly propelled to a growth point and attach.

- 3-D design – Generic infrastructures have little consideration for the lifestyles of their marine neighbors. Species like octopuses and fish look for nooks and crannies to take shelter from predators, breed, and hunt for food. Species that thrive in intertidal zones (often constructed as ripraps or revetments) like sea anemones or shrimp, rely on water-retaining zones, such as tidepools.

ECOncrete also enables active carbon sinks to develop by enabling the aforementioned carbonation process to occur on structures themselves. The three part technology enables marine organisms that perform carbonation to grow. By providing a suitable substrate that encourages growth of marine plants and animals, which in turn provide habitat for a diverse range of marine organisms, including urchins, whelks, bivalves and other shelled organisms, carbon dioxide is naturally assimilated into the oceans, eventually sinking to the ocean floor when these organisms die. ECOncrete®‘s innovative solution also contributes to these processes by bringing concrete infrastructure to life, generating rich and diverse urban marine habitats teeming with fish, oysters, sponges and alike. ECOncrete®’s modified concrete also encourages growth of engineering species such as oysters, corals, and barnacles, whose calcium carbonate skeletons not only acts as a sink for carbon dioxide, but also increase the strength and durability of concrete structures to which they adhere.

When applied to the potential of marine infrastructure projects, the impact is massive. For example, a 1 km long ECOncrete seawall can store the same amount of CO2 every year as 100 trees. To provide more context, the U.S. is planning to construct 35,101.5 miles of climate-adaptation seawalls by 2040. If all of those seawalls were built with ECOncrete, it would be the carbon equivalent of reforesting an area 20X the size of New York City entirely in tropical rainforest.

Win-Win Solutions

For clients like offshore asset owners, urban waterfront managers, and more, ECOncrete can facilitate compliance with strict environmental regulations and climate action goals. By creating a carbon-storing ecosystem on infrastructure, ECOncrete can facilitate permitting, getting critical projects in the water faster, and reducing mitigation penalties by up to 80%.

These benefits are abundantly clear in New York City’s Living Breakwaters project. The chain of nearshore breakwaters are designed to nourish Staten Island’s beaches, while buffering damage from the next Hurricane Sandy. In this project, the ecological design which includes ECOncrete’s technologies dropped mitigation penalties from $18 million dollars to just $4 million.

When building protections against a changing climate, or innovating ways to reduce concrete’s carbon footprint, it’s time to build not only for strong infrastructure, but also for strong ecosystems.

It’s time to build responsibly.