Interlocking Armor Needs an Upgrade

Interlocking armor is used along many of our coasts and waterfronts as a versatile solution for building breakwaters, coastal erosion control, and land reclamation. Many of the traditional armoring units are problematic in the impacts they have on the environment, damaging marine life alongside high carbon footprints. Traditional concrete comes with large costs, both economic and environmental because it lacks ecological consideration during construction.

When coastal armor works with nature, there is a high return on investment. A $75 million project to construct 8 breakwaters along New York’s shores faced a $18 million environmental mitigation penalty cost for the infrastructure’s projected damages to the site’s environment. However, when ecological design changes and ECOncrete technologies were implemented in these breakwaters’ design, the project’s mitigation penalties dropped to only $4 million.

A Solution for Industry-Standard Coastal Armor

Traditional interlocking coastal armors have smooth, flat-plane designs and harsh chemical compositions that make it difficult for marine ecosystems to thrive on and around these infrastructures. When the armor is placed in intertidal zones to protect from wave action or control erosion, the structures do not replicate the form and function of natural coastal systems, therefore destroying natural habitat without a replacement.

The Port of San Diego was searching for a structural solution that would not only protect port assets but also help adapt to climate change. They sought project benefits for the local economy, community, and environment. ECOncrete worked with the Port of San Diego to design an armor unit that is structurally sound and provides native habitat in a riprap scheme.

The COASTALOCK Trifecta

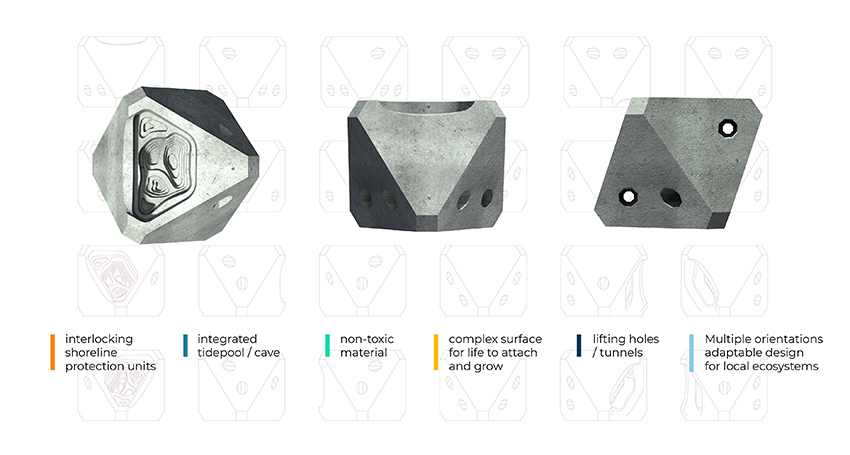

COASTALOCK is an interlocking single-layer concrete armor unit designed to perform for project and planet.

“COASTALOCK is the trifecta we love: carbon sequestration, smaller footprint, while at the same time, providing resilience.”

Jason H. Giffen, Vice President of Planning, Environment, and Government Relations, Port of San Diego

The COASTALOCK has micro and macro features that allow marine organisms to grab on and thrive. In contrast, traditional concrete armor’s smooth surface provides no indents or grooves for organisms to grab onto, resulting in a bare, lifeless surface.

By mimicking the world’s greatest engineer, nature, COASTALOCK encourages bio-protection: biodiverse marine life which grow on the structure and create a protective layer that shield the concrete from physical and chemical degradation. With bioprotection, the magnitude and frequency of structural maintenance is reduced, resulting in improved ecological stability and a greater return on investment.

“Environmental benefits and social benefits also produce tremendous value. Whenever we can generate more value by spending fewer resources and creating multiple public benefits, that’s smart, that’s good business, that’s positive leverage and that’s what we should be doing.”

Rafael Castellanos, Board of Commissioners, Port of San Diego

There is a cavern in every COASTALOCK armor that can retain water at low tide. When the unit is rotated, however, the tidepool can also become an overhand or cave, providing shelter and breeding habitat for species that need different conditions. The ability to interlock at any orientation not only accommodates sensitive marine species, but also allows for versatile and flexible infrastructure arrangements. The units have been specifically developed so that they are able to be deployed on very steep (upto 1V:1H) sloping shorelines. The shape of the tide pools provide for interlocking between adjacent units which further improves stability when exposed to intense waves and currents.

Most interlocking armor solutions can incorporate ECOncrete’s admix and texture technology, and most standard rock ripraps, revetments, and breakwater concrete single-layer armors can be fully-replaced by COASTALOCK to create natural and efficient shoreline systems. At the Port of San Diego, ECOncrete’s technology replaced sections of the rock riprap with armor well-suited for the Port’s future: effective, efficient, and climate-adapted.

With sustainable planning, incorporating marine-friendly infrastructure can help ports build for the future.

Read also: