How ECOncrete Works

The ECOncrete solution consists of three core elements that work in synergy to enable the growth of biologically diverse marine life on concrete infrastructures.

Reinforced by nature

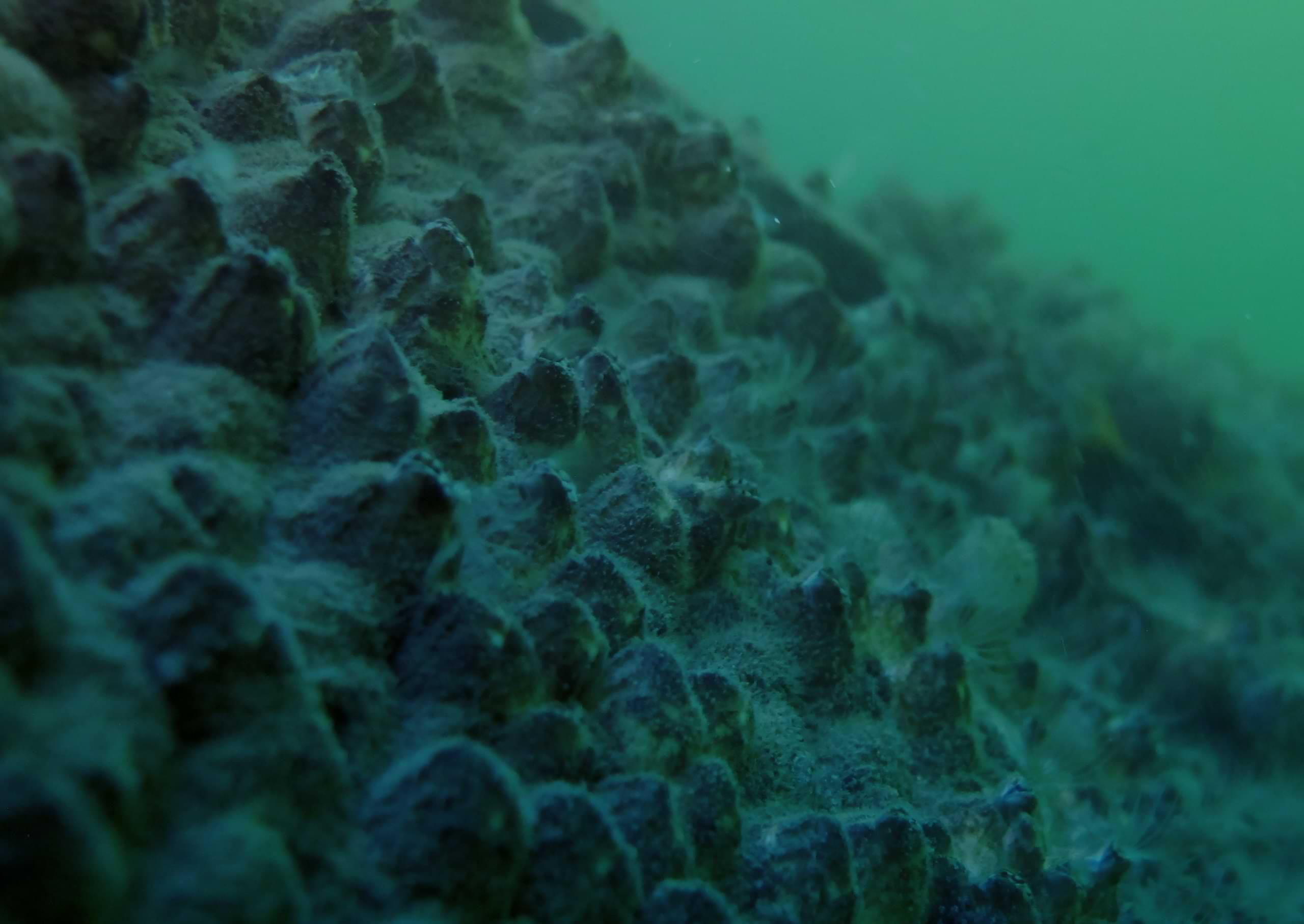

ECOncrete's technology addresses the chemical composition, surface texture, and nature inclusive design of concrete marine infrastructure. This promotes the growth of organisms like oysters, corals, or barnacles, which act as biological glue, enhancing the strength and durability of structures, and adding to their stability and longevity. We call it bioprotection.

Bio-enhancing concrete compositions

Our life-enabling admixture can be added to regular concrete mix to create chemically optimized concrete that encourages healthy and diverse marine life to develop on it.

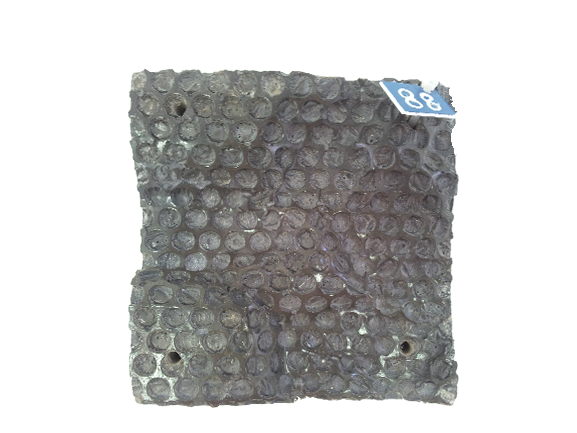

Texture agents

Our mold-modifying agents, liners, and coatings create complex surface textures on which growth is enabled, allowing for rich, diverse marine life to develop.

Science-based molds

The nature-inclusive design of our molds and mold-inserts, enables the creation of ecological niches. These support the ecological uplift of infrastructure and provide added bioprotection, delivering increased strength and durability to the structure.

Fully compliant solution

ECOncrete® meets or exceeds the following international standards:

- EN 206 / BS EN 206

- EN 934-1 2008

- EN 934-2 2009 + A1 2012

- ASTM C494 / C494M

- AS 1478.1-2000

- SI 89

- CE

- EPD

Concrete that partners with nature

is STRONGER

Thanks to the innovative admix composition, as well as ECOncrete’s texture agents, and mold designs, a living layer of oysters, corals, tubeworms, and more grows on ECOncrete structures. This hard layer protects concrete from weathering and buffers hydrodynamic forces.